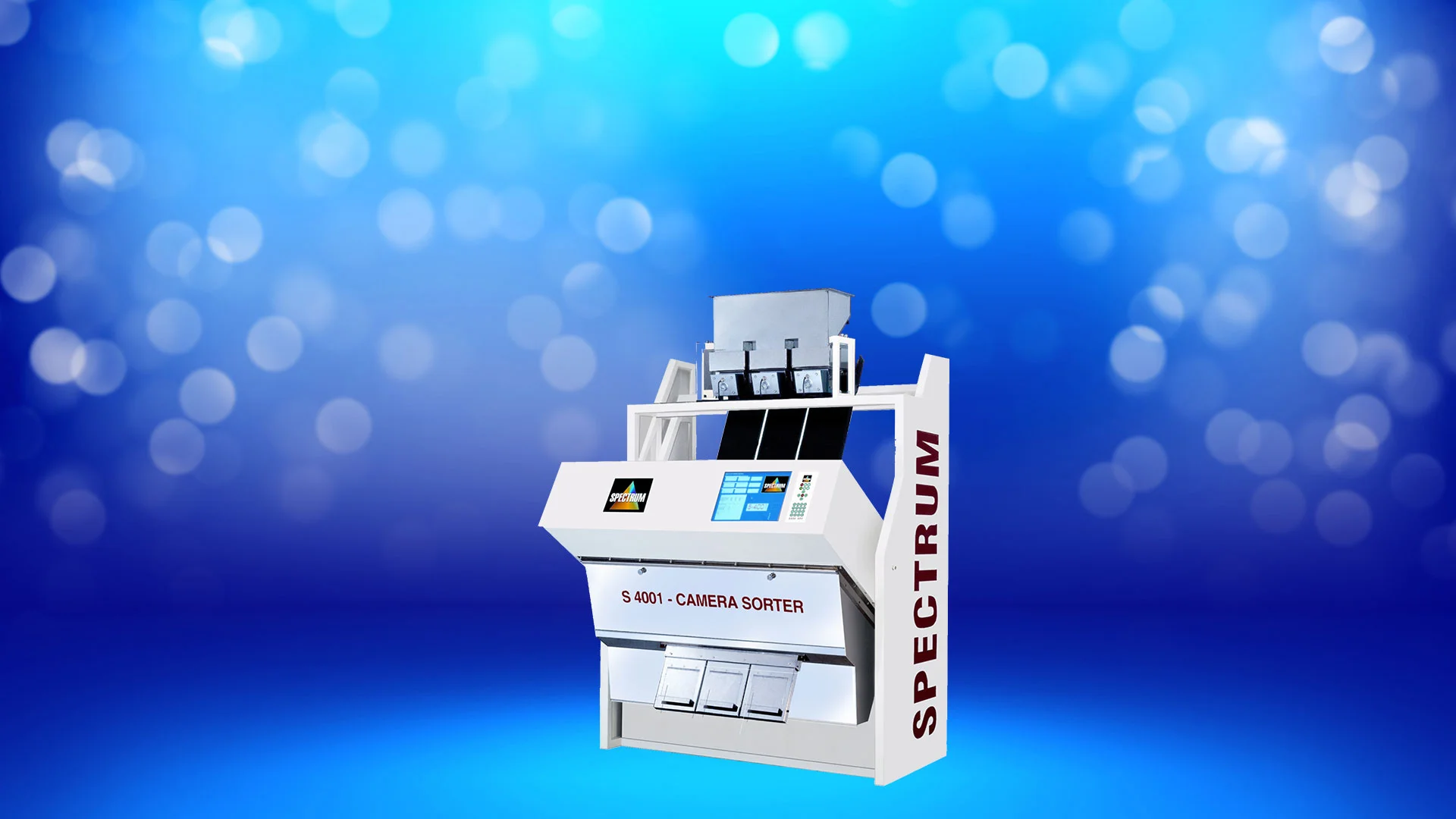

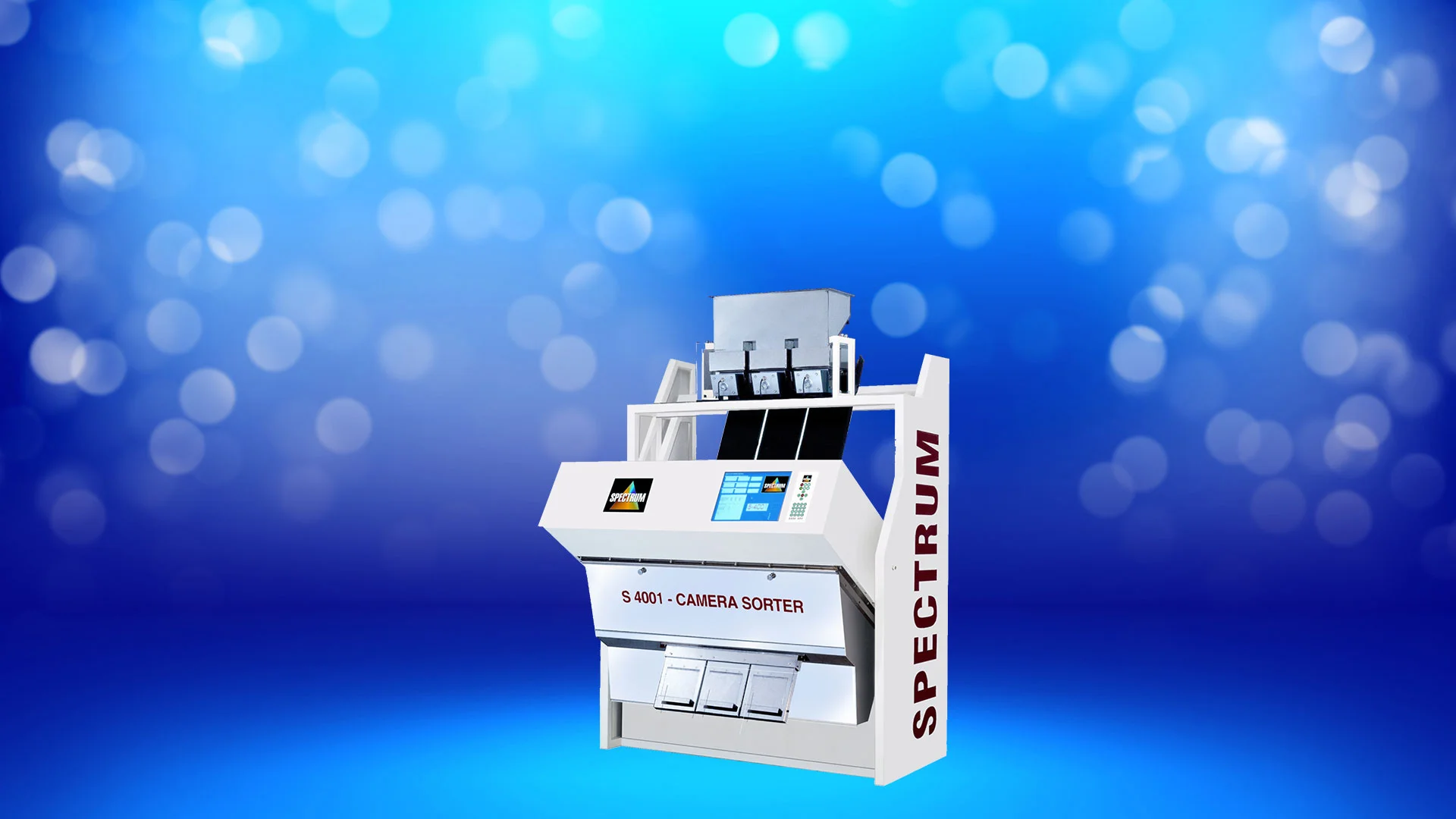

Color Sorter Machine

S-4001 MAXIMA Trichromatic Sorter

What is it ?

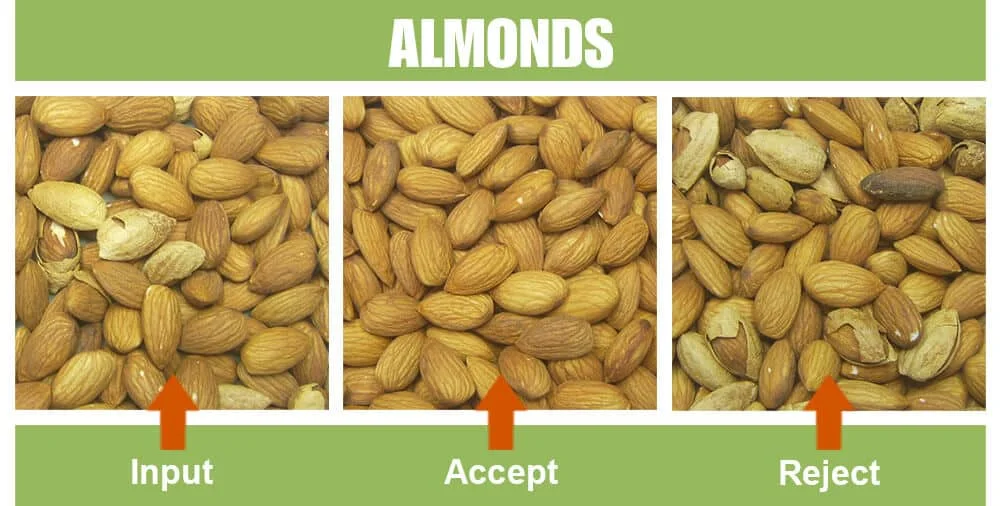

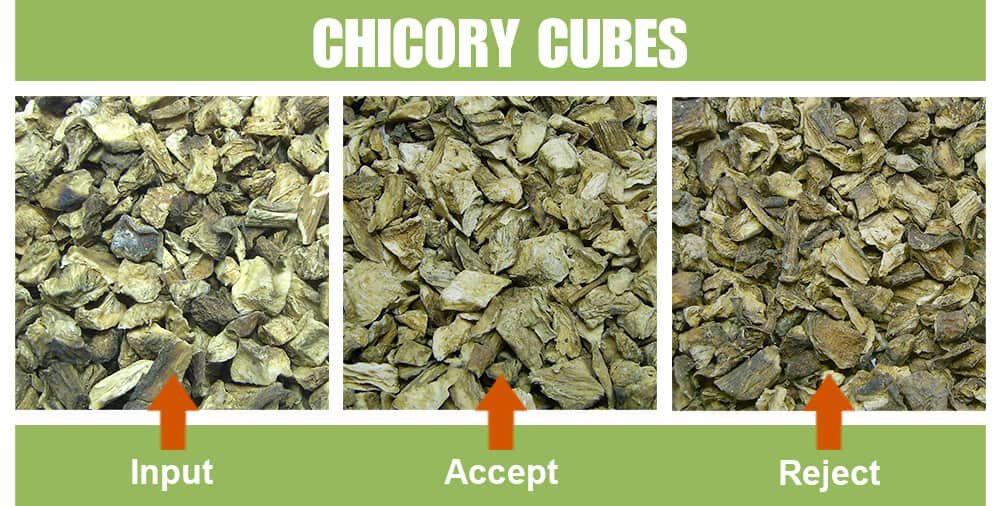

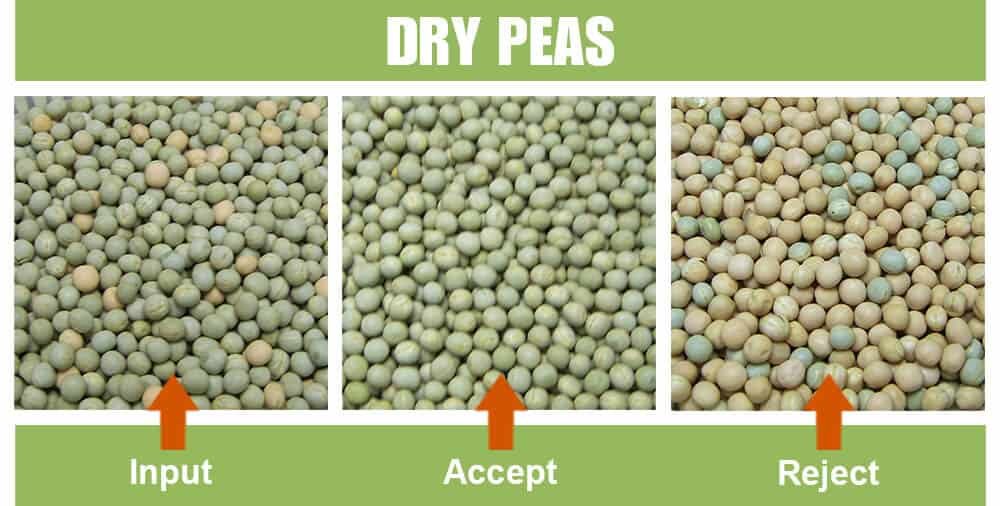

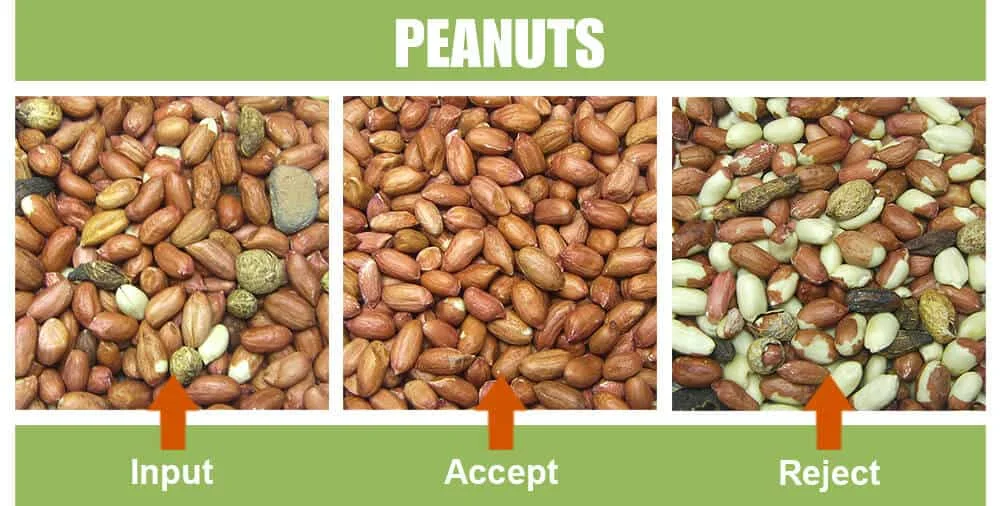

The SPECTRUM S-4001 MAXIMA series Trichromatic, RGB (Red, Green, Blue), CCD Camera based color sorters are the culmination of the efforts of constant R & D in color sorting systems, of over two decades at SPECTRUM INDUSTRIES.

How it works ?

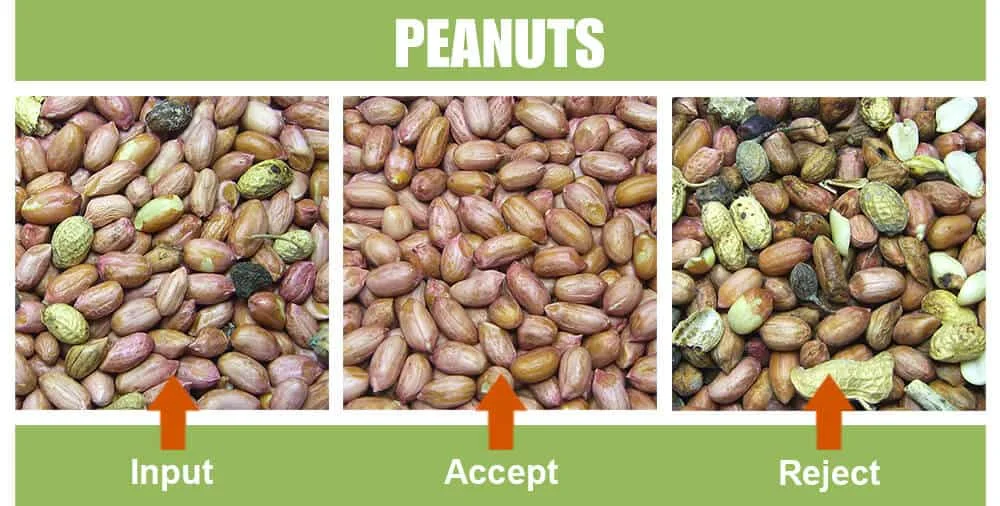

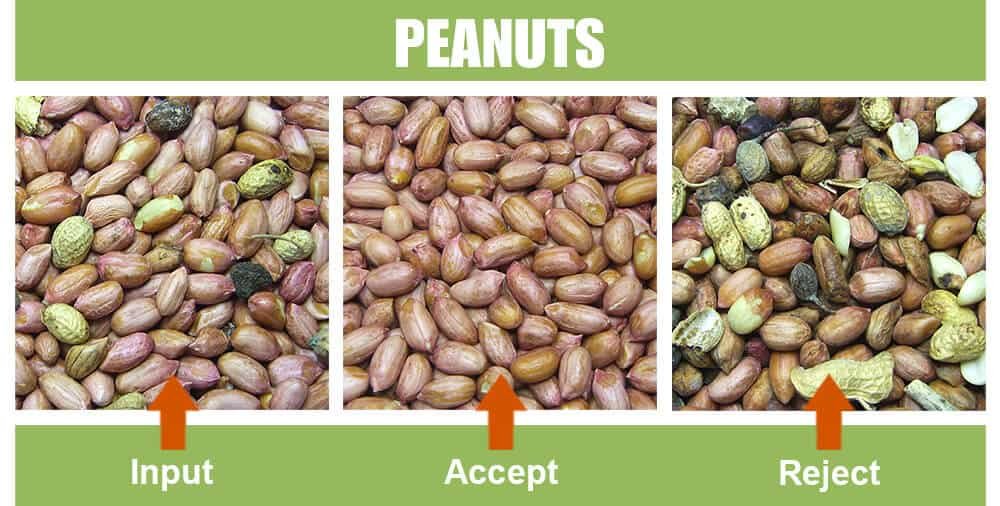

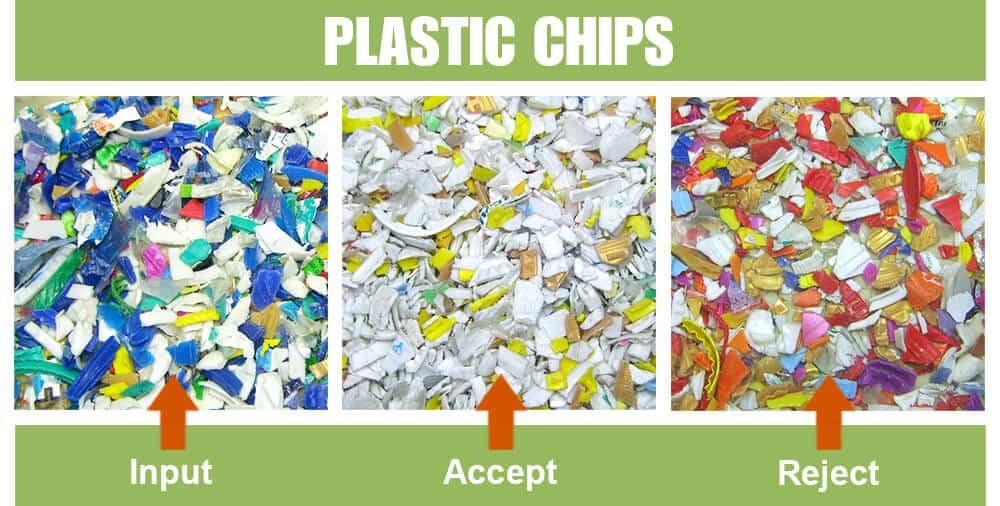

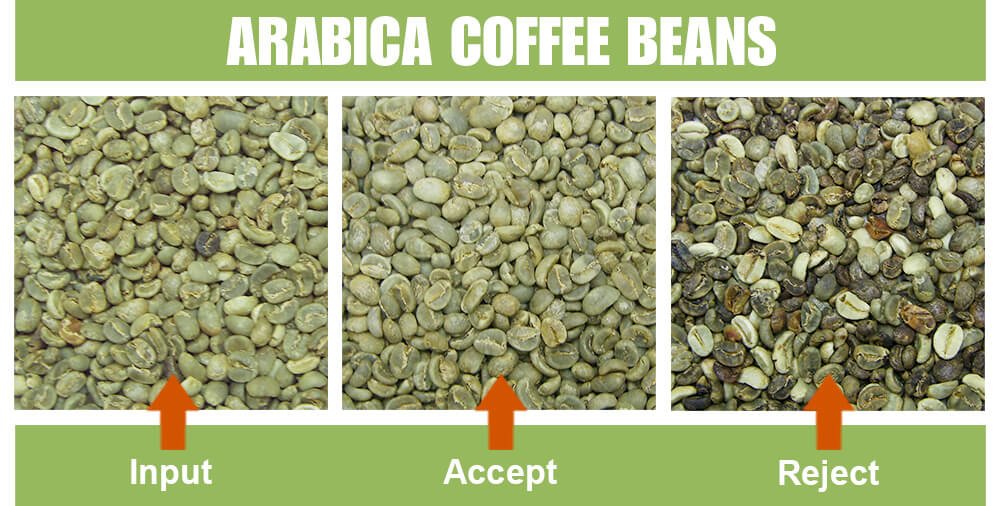

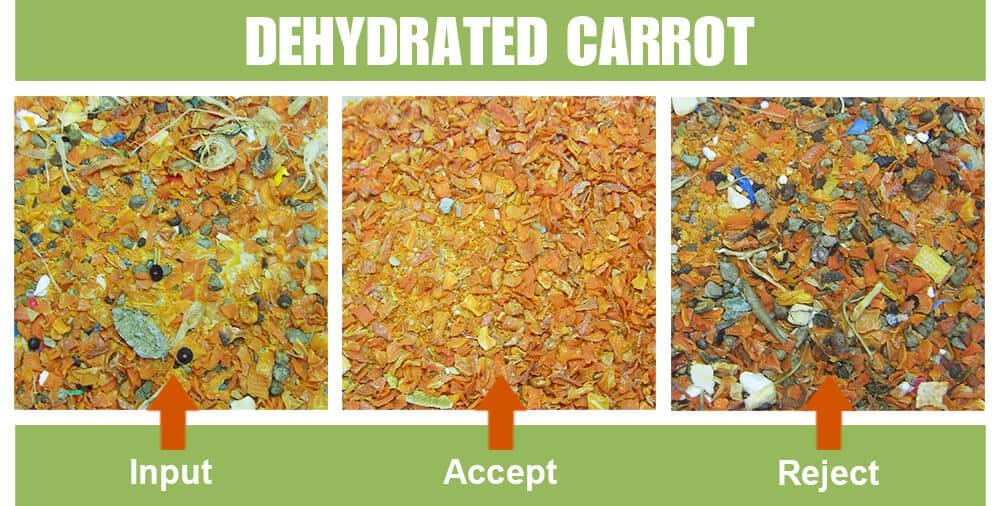

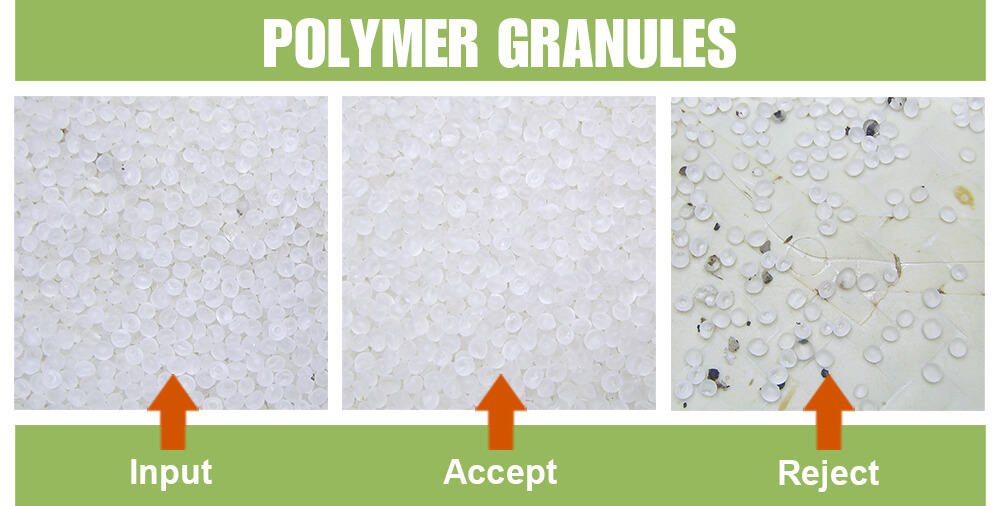

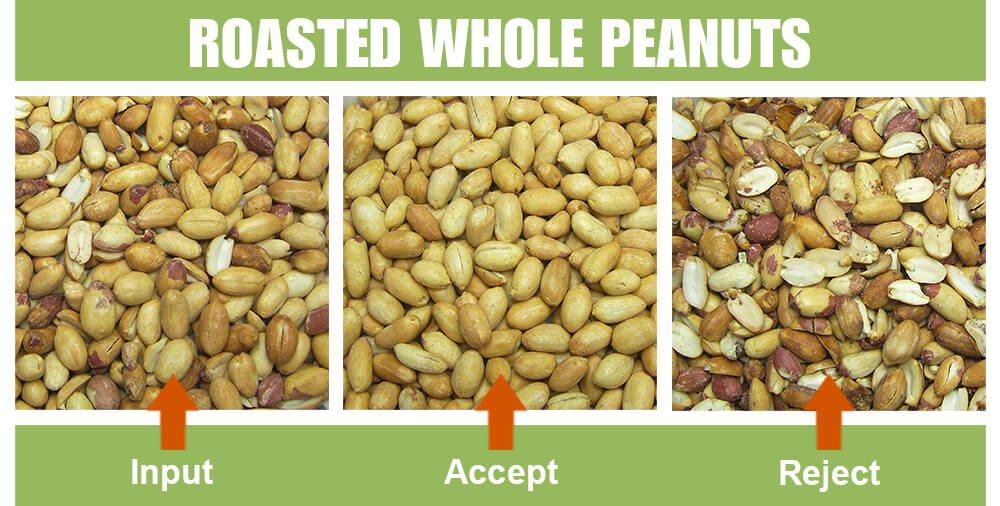

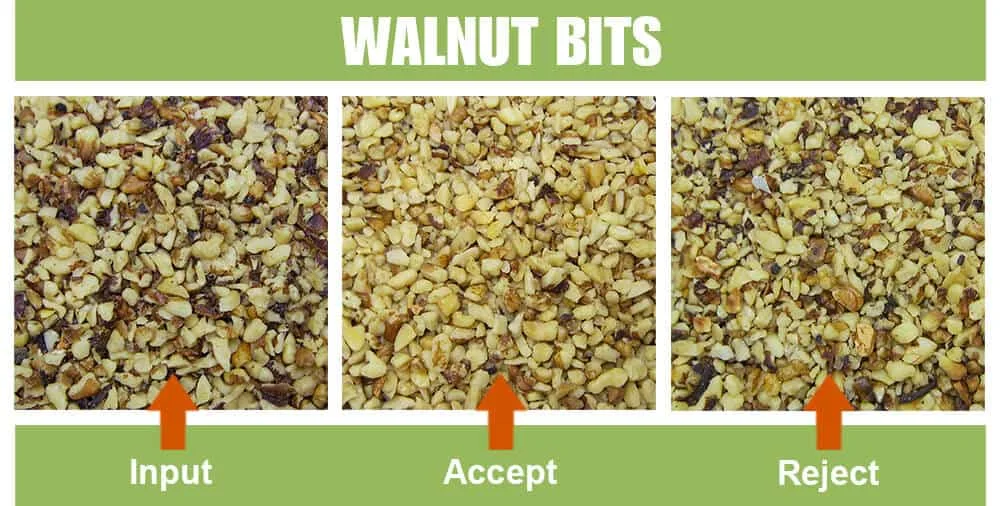

The S-4001 MAXIMA use advanced 5400 pixel x 3, Tri-linear RGB, CCD Line Scan Cameras to scan the product in the Red, Green and Blue region of light in order to identify even subtle defects in product quality.

The S-4001 MAXIMA is available with Penta-chromatic, LED Solid State High Intensity lighting for far sharp illumination of the product being sorted. The combination provides high resolution imaging that is displayed on a 15” Colour LED TFT screen, for online viewing of the product. The resultant data is compared with pre-set parameters, to reject the defective product using ultra-fast, long life custom designed pneumatic ejectors.

The S-4001 MAXIMA has the ability to detect and reject over 200,000 objects/minute with a defect size of even 0.025mm sq. The Penta-chromatic LED solid state lightning provides high intensity stable lightning with extremely long life, giving the machine the ability to sort multiple products with ease on the same machine, without any requirement whatsoever to change the lightning for sorting multiple products.

The S-4001 MAXIMA is fully computer controlled with automatic calibration and self-check procedures.

Instant change over from one product sort to another is possible, using pre-stored sorting Algorithms.

Features

- Trichromatic RGB (Red, Green & Blue), CCD Line Scan cameras.

- High Resolution with 5400 pixels 3, tri-linear CCD Camera.

- Penta-chromatic LED Solid state high intensity long life stable lightning.

- On-Line live visual display of product being on 15 Colour LED TFT screen.

- Ultra-fast long life pneumatic ejectors with response time of 1ms and life up to 5 billion cycles.

- Automatic cleaning of viewing area by wiper system.

- Automatic online calibration with self-check procedures.

- Fully computer controlled.

Benefits

- Optical sorting helps improve product quality,

- Maximize throughput

- Increase yields while

Application Industries

- Food Processing

- Grains Processing

- Plastic Recycling

- Tobacco

- Cashew Processing

- Rice

- Wheat

- Barley

- Groundnut

Packing & Shipping:

- Machines are carefully packaged to endure transportation under harsh conditions.

- Handling instructions are designed to protect the machine in the critical moments during transportation, unloading and installation.

- Delivery Time: 20- 30 Days after order confirmed.

- Payment Terms: TT, Letter of Credit.

Commissioning & Installation:

- On Site Installation and Training Service by our professional engineer.

- Study and Learn the Machine Operation in Our Factory.

- Responsive in 24 hours: Telephone, Email, Video or On Site Solutions by our Technical Experts.

After Sales Services:

- With presence in a variety of countries, Spectrum Industries is strongly committed to being close to the customer.

- Through cooperation with loyal and carefully evaluated and trained local employees and partners, Spectrum managed to provide fast, competent and rooted services in the context of customers.

- Application centre in Mangalore production base offer demo machines for tests and comparison.

- A strong central technical team in India is supporting local channels with training, advice and technical support.

- Under normal working circumstances, Spectrum machines enjoy 1 year of full warranty and a lifelong warranty on the machine structure from the date of purchase.

- Service line is available for emergency support.

- Spectrum products will be serviced and supported wherever customers are located.

- Through the global Spectrum network and from Spectrum technical experts, training on Spectrum machines is available worldwide.